Client Backstory

A reputed client from the steel industry

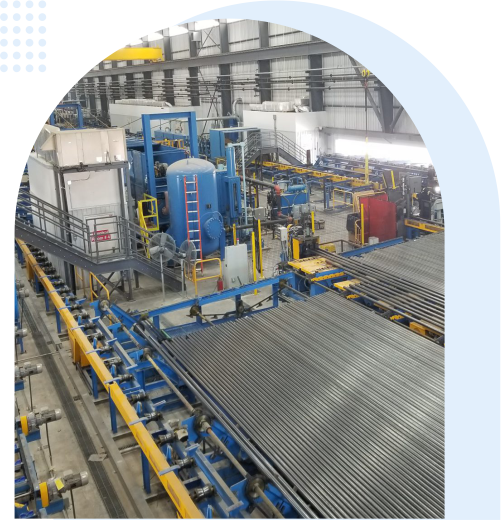

The client is a well-known brand in the Steel manufacturing industry.

Challenges

- High number of incidents at the factory.

- Prohibit unauthorized access to a restricted area.

- Challenges in following safety compliances.

- Incurring high cost and time spent in training.

- Loss of productivity.

- Integration of BLE connected Sensors and identifying worker position were required to show during the incident view.

- Achieving high accuracy on incidents in a short period of time where we have few samples vs our requirements.

- Connecting various components/processes on a single page where the client can view the incidents.

Strategic Approach

The client's requirements were feasible, but the challenge was to integrate BLE based hardware along with AI/ML process which is a 3rd party system.

We analyzed the clients' target audience, problem, and the challenges they are facing after discussing the goals they need to achieve. As the client is into the steel manufacturing business, they wanted to minimize the risk of accidents occurring in their factory. So we identified the ways in which it can be achieved. To eliminate and minimize the risk, we suggested implementing a video analytics solution wherein we can capture the second camera frame and analysis of each and every second. It will also send alert to workers and management in case any incident happens and later on, the supervisor can use such video for training purposes.

Before the actual project started we collected the following documentation to ensure we are building the right application:

- RFP

- SOW

- Design documents

- Sample Data

- BLE based hardware SDK

- Achieve an effective replacement for their existing monitoring system with Automation using AI/ML.

- Make safety measures followed by factory staff and visitors more accurately and efficiently.

- Avoid vigorous monitoring by security staff personnel over the CCTV

- Eliminate the manual requirement of informing the higher authority when an incident happens

- Coach/train staff from previous incidents

- Implement a system for workers' safety measures.

- In case someone fails to follow the rules, the higher authority should be notified.

- Reduce human errors and their limitation by applying AI/ML on the top of DL

- Validate all incidents that take place

Impact

- The business observed a dramatic reduction in the number of incidents by over 15%

- The automated system helped the business in increasing the productivity of its workers by 10% in certain sensitive zones and areas, that were prone to higher risks earlier.

- Reduced legal litigation risk, cost, and training expenses, which resulted in positive operational efficiency.