Figuring out how to thrive in a competitive business world? Adaptation is the key to winning and thriving. Embracing technological trends is an undeniable fact in the manufacturing industry. Technology is reshaping the industry across all fronts from strategic to operational transformations.

In the technology-driven economy and customers becoming smarter, it became essential for manufacturers to offer connected products to its customers, which is possible with the help of smart manufacturing facilities. The fourth industrial revolution (Industry 4.0) has superhuman efficiencies, wherein manufacturers are not just makers, but the thread that connects the entire life cycle of the product by harnessing the breakthrough innovations in the technology.

Technology has enabled them to design smart and intelligent operations that increase the speed, decrease the cost of production, and open up new revenue streams. Technology helps the manufacturers to unlock exciting opportunities; however, they don't come without challenges, the high level of flexibility and adopting a customer-centric approach is forcing them to restructure their businesses. The performance pressure is imposing manufacturers to seek control over all their operations from raw material to value chain; therefore they are adopting smarter ways like vertical integration, technological-integration, and Intelligent supply chain management to improve efficiency.

Emerging Manufacturing Trends

From Intelligent manufacturing to intelligent supply chain management, technological advancements are synchronizing various business functions and providing real-time visibility to manufacturers. They are enabling users to work faster and smarter to meet evolving consumer needs. The emerging manufacturing industry trends that are opening the door for a new breed of intelligent manufacturing are:

Additive Manufacturing (AM) making designing easier

The 3DP (3D Printing) manufacturing process is helping to simplify the complex objects and structures by slicing them into layers. It is changing the value chain thereby leading to efficiency, growth, and transformation of the manufacturing sector.

Artificial Intelligence and Machine Learning driving the decision-making

Artificial Intelligence and Machine Learning help to make data-driven decisions and provide valuable insights. It helps the manufacturers during the entire life cycle of the product, from raw material sourcing to final product delivery. AI-infused RPA is the new trend that addresses the supply chain deficiencies.

Cloud motivating to go serverless

Manufacturers are increasingly using cloud services to expand their physical product portfolio, as it allows scalability at a low cost. It opens a broad range of services like Manufacturing as a Service (MaaS), Product as a Service(PaaS), Equipment as a Service (EaaS), Simulation as a Service (SIMaaS), Management as a Service(MaaS), Maintenance as a Service (MAaaS), and Integration as a Service (INTaaS) which embraces the service-oriented models.

Industrial Internet of things (IIoT) offering a continuum of connectivity

Technologies like 5G, broadband, edge computing, and mesh networks are driving product development. The deep insights provided by these technologies help to keep updated in the dynamic business world.

When human-centered designing meets edge technologies

When intelligent interfaces like Augmented Reality(AR), Virtual Reality (VR), auditory analytics, and computer vision are integrated into the manufacturing process, it creates wonders and reduces human efforts substantially.

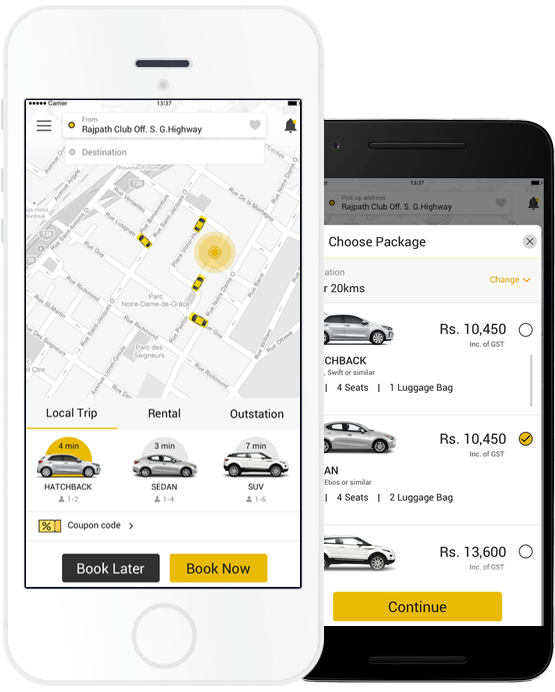

Customization to enhance customer experience

The data collected from sensor-enabled devices and social media help manufacturers to understand customer behavior and reach out to the target market easily.

Manufacturing business welcomes Cobots (Collaborative Robots)

The cobots are improved versions of robots and with their computer vision can identify flaws, automate transportation, and undertake predictive analysis to avoid hazards. Moreover, they do not replace human efforts but augment it.

Key Challenges in the Manufacturing Industry

No industry can grow when things are easy, the manufacturing industry is not an exception, it will grow when it faces challenges and if it faces challenges it will change. Industry 4.0 has revolutionized the manufacturing sector, however, the transition is not easy and had given rise to the following challenges during its implementation:

Big data posing big challenges

The insufficiencies in standard data management are forcing companies to manage a large amount of data unnecessarily; also, the responsibility of securing and controlling such data impose an additional burden on the manufacturers.

Emerging technologies are not easy to incorporate

The encapsulated structure of manufacturing does not easily allow the integration of emerging technologies into their systems. From the intelligent requirement of equipment to training the workforce, the dynamism of technology brings in complex challenges related to managing change.

Cybersecurity challenging the reputation

Technology increases vulnerability and risk. Hackers are targeting the production facilities to identify the security holes, which is not only harming the individual but also the reputation of the producer. The challenge is more prominent in the manufacturing sector due to the inability of the companies in paying essential efforts towards security.

Escalating capital investments

The new technologies like AI, RPA, nanotechnology, and biotechnology are imposing the companies to increase their capital investments, thereby increasing the cost of the final product. However, in the competitive world, customers are demanding the best quality product with at least price, which is making it challenging for manufacturers to manage.

Changing customer expectations increasing the gaps

Engineered-to-order products are decreasing the standardization system and increase the complexity of products, thus manufacturers are required to train and develop skillful employees to address these gaps.

Project management enhances rigidity

The projects in the manufacturing industry are highly sensitive to cost, time, and quality, which makes them rigid and highly controlled. In order to manage the project effectively, modern automation software can be of great help.

The power of technology is beyond human capabilities. The integration of intelligent and traditional manufacturing practices are producing highly positive outcomes, as a result, manufacturers are increasingly migrating towards new business models. It allows the manufacturers to add products to their portfolio, build trust, acquire momentum, and gain a competitive advantage. The biggest challenge that the industry is facing is not managing the technology but the people. The insecurity, resistance, and inefficient change management strategies are significantly hampering digitalization. This cannot be changed overnight; however, transforming the processes and workforce makeup gradually will certainly help in the future. The journey ahead is full of possibilities and the forward-thinking organizations are already capitalizing on IT business models, whereas digital novice is juggling hard. As per the PWC survey, 72% of manufacturers are dramatically moving towards digitalization. Thus the drumbeat of digitalization continues to grow louder.

Rediscover possibilities by harnessing the power of disruptive technologies

Related Articles

Achieving Success Through Innovative Solutions

Transforming client businesses through state-of-the-art creativ